Designing a Conveyor Lighting System

Conveyor lighting systems often operate in some of the most challenging environmental conditions for any lighting system. The industrial nature of the operating environment means they need to withstand the harsh conditions of vibration, high ambient temperatures, dust and cyclonic winds. The potential need for continuous luminaire maintenance can lead to costly downtime and is a major consideration when designing conveyor lighting.

Conveyor lighting improvements

One of our most popular conveyor lighting products of the past few years has been the Coolon Static Retro. It is a strong performer for us because it’s proven to be fit for purpose, offering cost and energy savings for operators over its product life cycle.

Hungry to continuously improve our product range, we decided to go back to the drawing board and further push the performance boundaries of conveyor lighting systems. One of the major leaps forward was a sleek, solid body design, formed out of a single piece of the finest grade aluminium alloy. Aesthetically refined, it was designed to be lighter, stronger and completely resistant to vibration. Great importance was also placed on ease of handling, assembly and heat dissipation.

The DLK LED conveyor luminaire is born

Rather than trying to improve on the existing Static Retro, Coolon decided to start with a blank canvas. This way, we were not limited and constrained by what we thought we knew and what the industry had accepted as standard. It is with this creative spirit the DLK LED conveyor luminaire was crafted.

Engineered with purpose

Every millimetre of the DLK has been engineered to serve a particular function. Its shape and size purposefully designed to allow easy retro-fitting onto existing pole and spigot mounting.

The DLK is enhanced with the addition of intelligent communications for active dimming and thermal management due to the extreme temperature the system is exposed to. Temperatures can exceed 45 degrees Celsius on Australian mine sites rendering most LED luminaires completely useless when not fitted with sophisticated thermal management technology.

Unlike many other LED luminaires used in conveyor lighting systems, the DLK body is designed not to exceed high temperatures, ensuring dust or dirt does not bake onto the optical surfaces. The DLK can be easily cleaned and high pressure washed to bring it back to pristine optimal operating condition.

LED mining applications

Great emphasis was placed on the LED's optical performance. Lighting in mining has been traditionally used to provide sustainable and safe working conditions for personnel, typical governed by Australian/World lighting standards or safe lighting practices. The DLK LED Industrial Conveyor light has instant restrike, thus not affected by brown outs. The luminaire switches on instantly to full brightness without the need to warm up or cool down.

Adaptive light spectrum

The DLK produces high quality white light with a high colour rendering spectrum. This means the colours appear vibrant and true to their source, allowing them to be easily identifiable. The DLK is further complimented by various Colour Temperatures (CCT), available in a warm white colour for foggy conditions, where more of a yellow spectrum is required. The DLK produces light that does not flicker, improving safety in areas where operators are exposed to moving or rotating machinery.

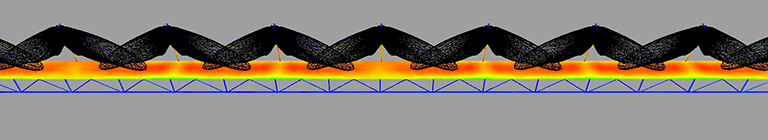

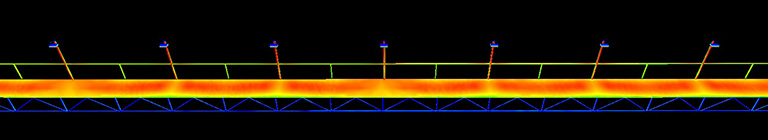

By designing optics specifically fit for the application, we were able to direct the light precisely where it is needed. Utilizing a single piece of polycarbonate allowed us to push the light further, whilst minimizing what is usually a labour intensive process of placing individual optics on each and every LED. See more on product streamlining.

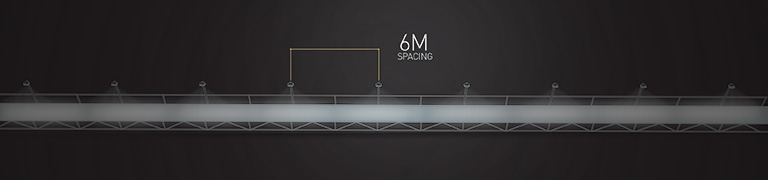

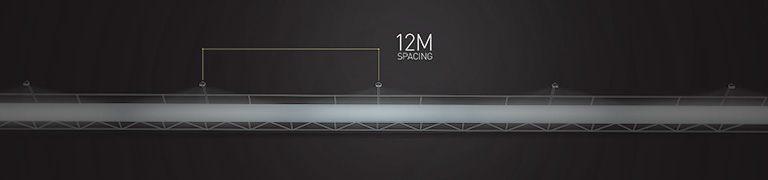

Typically a conveyor belt required 40 lux. In the past this was achieved by placing luminaires 6 meters apart along the length of the conveyor system. The DLK optical design and efficiency allows the luminaire spacing to be extended to 12 meters apart along the length of the conveyor. This means half the number of luminaires are required, which translates to significant cost savings to the customer.

Decreased power consumption

The DLK consumes significantly less power than conventional luminaires. To further reduce power consumption, the DLK features an in-built daylight sensor which automatically dims the light when it is no longer required. This created a reduction of running costs on a scale like we’ve never seen before.

The DLK was carefully designed to streamline the assembly and testing process in order to lower the production costs as much as possible, whilst maintaining the highest level of quality. Great effort was made to ensure the manufacturing process avoided labour intensive practices. Our streamlined process translates to a lower costing product, allowing us to pass the cost savings straight to the customer. Payback periods of less than one year are routinely achieved by our customers. A relatively small investment in switching over to DLK has been proven to provide significant cost savings. See chart above.

Durability

The DLK durable design means it can sustain severe environmental punishment. An impact rating of IK09 and ingress protection of IP66 ensures it outshines and outlasts any other industrial luminaire on the market. Its LED light source has an expected degradation life of over 50,000 hours to 70% brightness. Meaning the 40 lux is still achieved after 50,000 operational hours. This long life makes the DLK a guaranteed solution that will cut down the need for scheduled lamp maintenance, which is a major cost for mine operators.

DLK conveyor lighting system proven in harsh conditions

The DLK LED industrial conveyor lighting system has already been installed is some of Australia’s harshest and diverse conditions. The salty planes of Dampier, the tropical cyclone capital of Australia in Karratha, the dry dessert of Newman, the humid tropics of Newlands and the damp surrounds of the Hunter valley, have had the DLK installed for well over 12 months without a single issue.

3 year warranty

The DLK comes with a comprehensive 3 Year manufacturer’s warranty as well as Emergency pack version for battery backed applications. All Coolon products are manufactured in Australia buy highly trained team in a state of the art facility.

Coolon is able to assist with the realisation of projects. Our team of industry experienced professionals are on hand to design conveyor lighting systems. We also provide return on investment calculations, performance/budget orientated solutions and general support and assurance when required.

For further information on the DLK or to learn the benefits of LED, please contact us.

To illustrate the differences in operating costs between the DLK and Conventional HID lighting systems, we've created the following infographic.

Mining Indonesia 2025 – Innovation in Action

Mining Indonesia 2025 – Innovation in Action

02 • 10 • 2025

Mining Indonesia 2025 was an outstanding reminder of what can be achieved when innovation and collaboration come together.

Coolon Unveils eLi: Lighting the Future of Curved Architecture

Coolon Unveils eLi: Lighting the Future of Curved Architecture

14 • 08 • 2025

Built on the legacy of our Aduro CL and Alto CL luminaires, eLi brings the same flexibility outdoors. With extreme durability, seamless curves, and breathtaking illumination.

08 • 07 • 2025

Coolon showcased its smart lighting solutions at Indonesia Miner 2025, supporting innovation, automation, and digital mining transformation.