Encapsulation Technology

Stunning light. Reliable performance.

Lighting has the power to set the ambience of a space. Just like a beautiful light can breathe life into a design, a malfunctioning luminaire has the power to ruin the whole environment. At Coolon, stunning lighting comes together with reliable performance. We use state-of-the-art technology to encapsulate our products that are specified for use outdoors and in demanding environments to make sure that our luminaires deliver not only enchanting light, but years of uninterrupted performance.

That’s the Coolon difference.

Elegant Encapsulation

Coolon’s unique technology protects luminaires and drivers without the need for multi-part enclosures and gaskets. The result is a seamless appearance, enabling many indoor luminaires to be protected and enhanced while retaining Coolon’s characteristic sleek, simple and aesthetically clean designs.

.png)

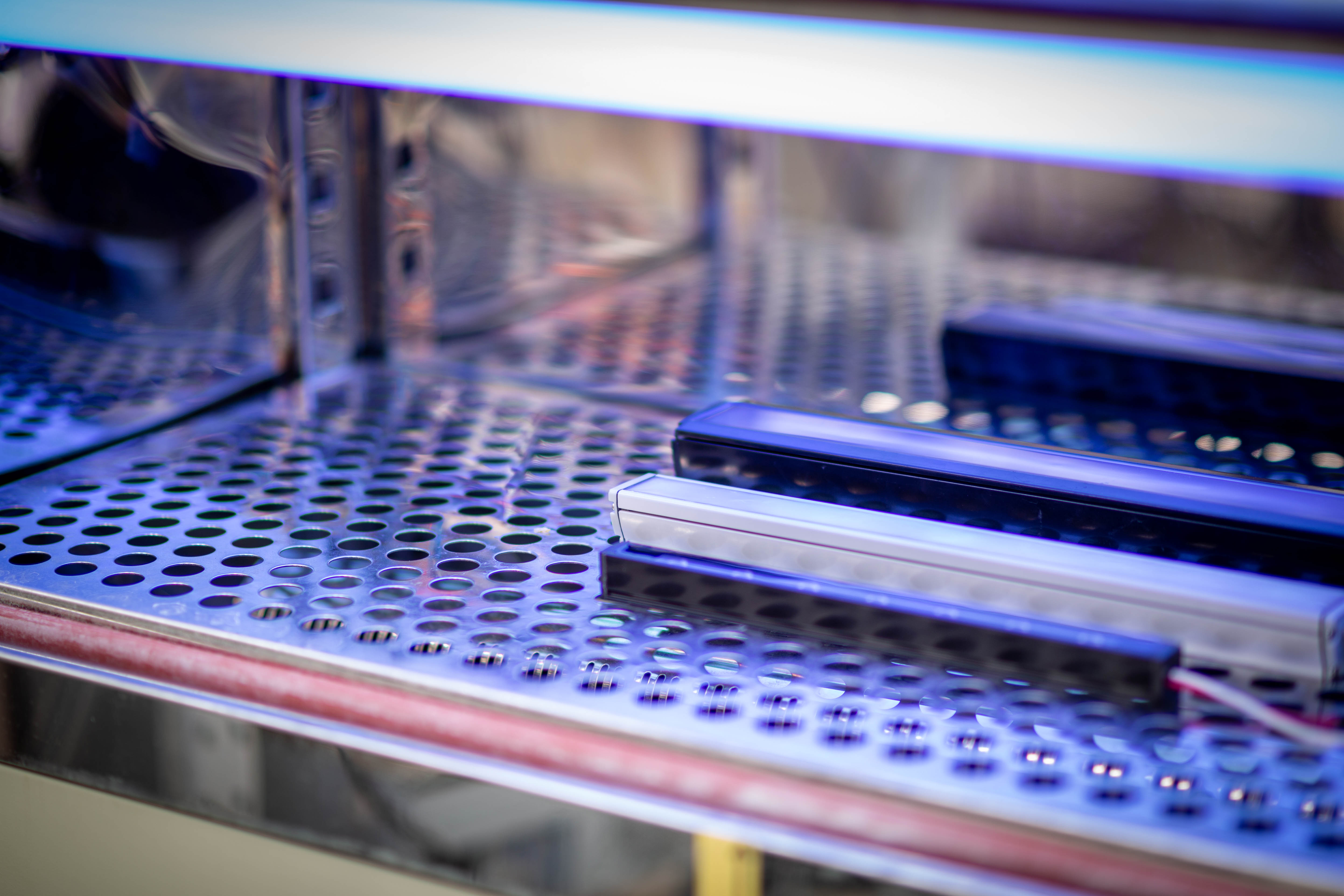

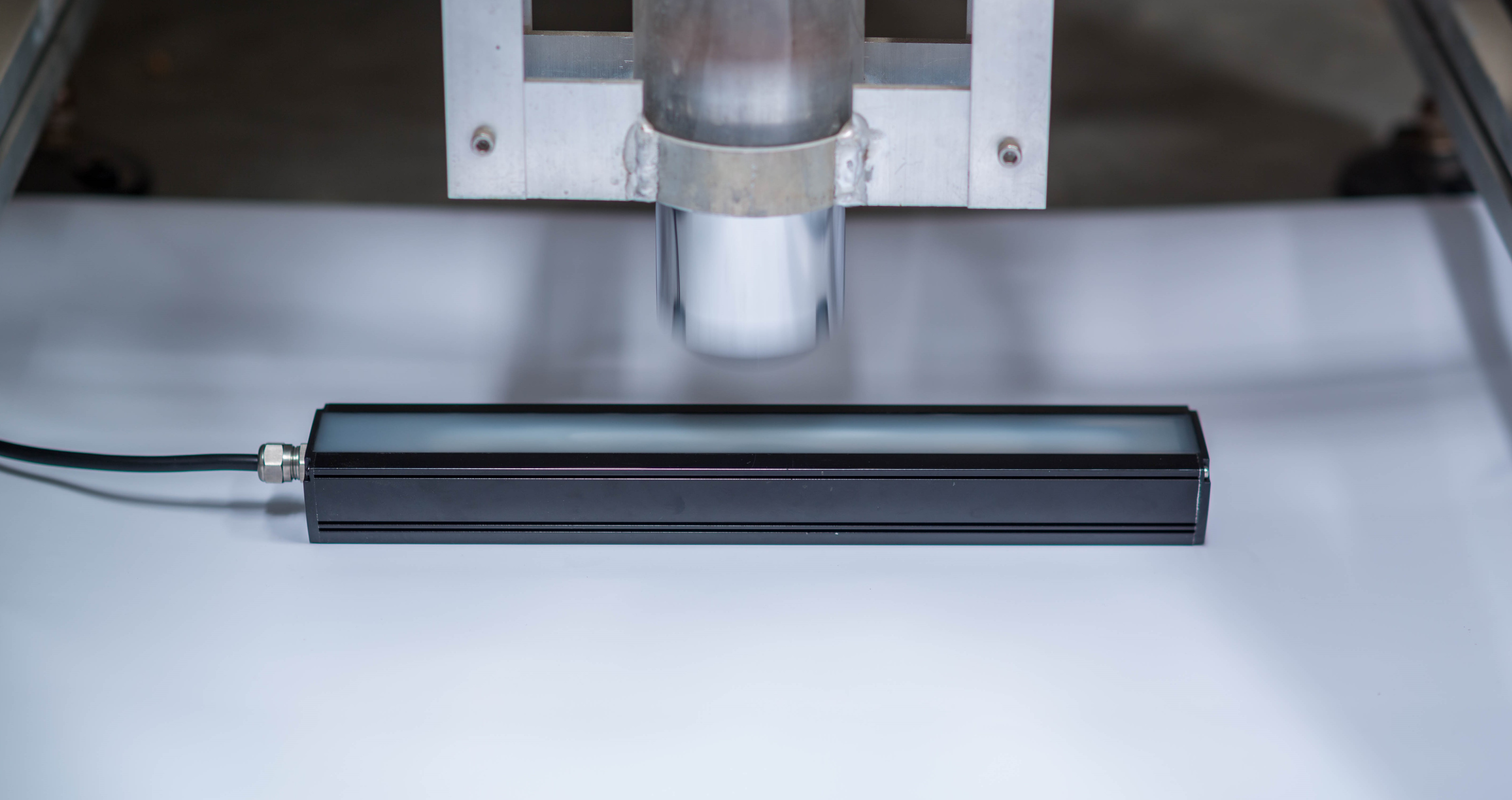

How our technology works

The encapsulation process involves a custom-designed 11-metre-long line from Demak group, equipped with two three-metre-long pouring beds that each incorporate an oven. Each project is unique, and the process is set-up and controlled by a skilled operator that manages the encapsulation process. As one of the final manufacturing steps for each made-to-order Coolon luminaire that requires it, each piece is arranged on the beds ready for encapsulation. A thermosetting polyurethane resin is precisely flowed into each extrusion and then allowed to solidify, first undergoing a polymerisation process in the low-temperature oven and then curing at room temperature.

.png)

What sets it apart

The materials are loaded automatically from storage tanks through volumetric piston pumps that are under continuous vacuum. This controlled dispensing system ensures that small air bubbles are removed and avoids additional risks seen in manual systems, including contact with contaminants. Our advanced low viscosity resins and precise curing processes ensure excellent adhesion to enclosure surfaces without shrinkage or volume reduction This clean and precise encapsulation method guarantees reliability, durability and quality, and provides multiple desirable physical characteristics and technical advantages.

.png)

Diffusion or clarity, where it’s needed.

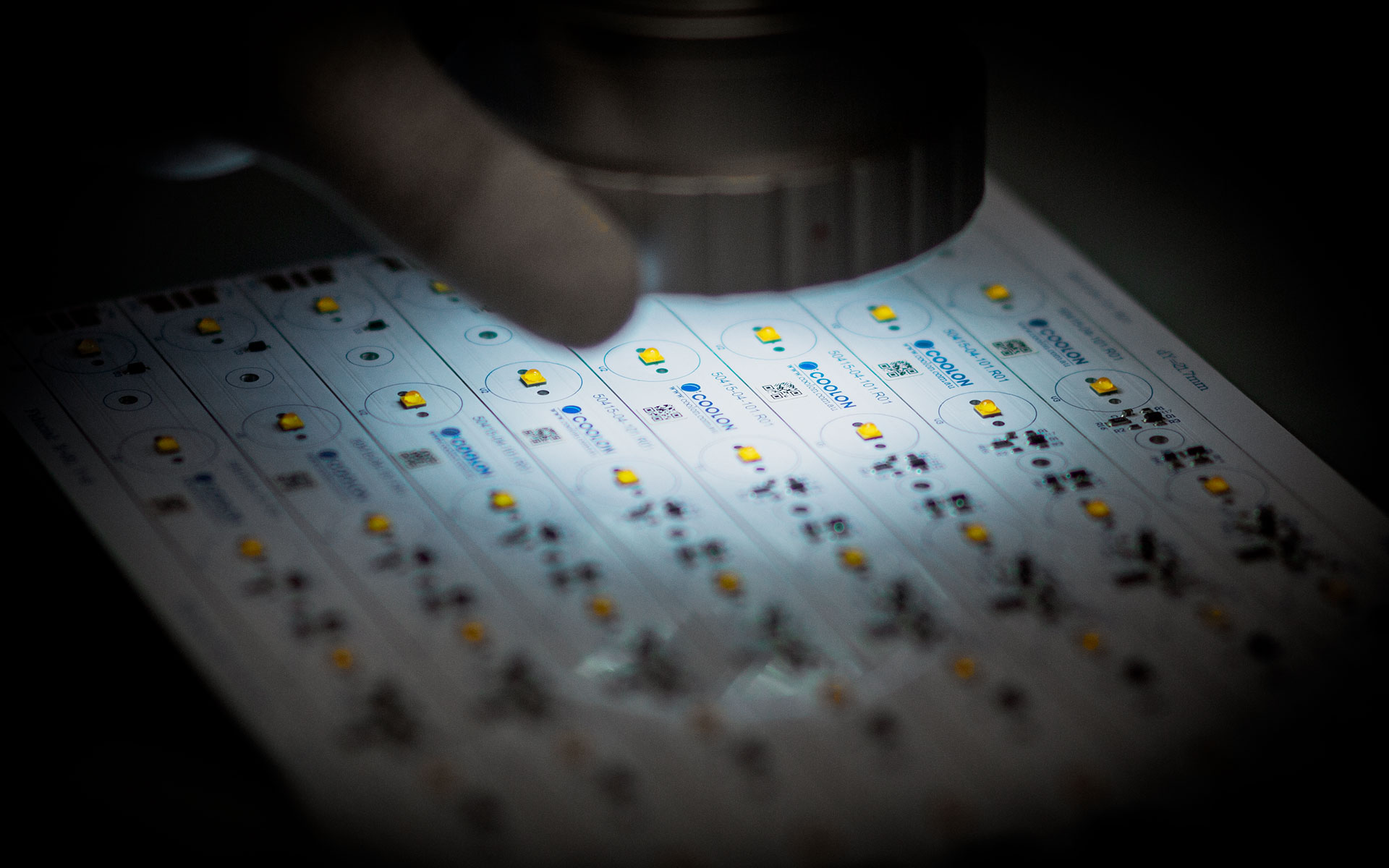

Coolon has tailored complex mixing ratios for each application using a two-component system. The material is dispensed from two tanks at a variable ratio of pure resin to hardening agent, while exact temperatures and software management guarantee a perfect mixing.

For our uniform glow products

A softer resin formula is placed within the luminaire profile, providing flexibility during normal operating temperature fluctuations. The luminaire is then finished with a hard, translucent layer that acts as a diffuser, providing a perfectly uniform illumination without any visible dots – perfect for direct view applications. Luminaires can also be installed close to vertical mounting surfaces with no risk of unsightly scalloping effects.

For our products with optical control

Each IP product with optics contains a specially designed and moulded potting envelope that sits over each optic. This ensures that the polyurethane resin doesn’t come into contact with the optics, which would fill the precise ridges and impede their effect. A clear resin is used over the potting envelope to ensure optical clarity, with the option of embedded micro louvres for glare control on some of our products.

.jpg)

For our inground products

Each seamless piece of acrylic in our Interra range has a precisely routed rebate to house its populated multilayer circuit board. To complete the luminaire, the acrylic piece is fully sealed with our polyurethane resin from the underside. The Interra segments can then be installed end-to-end to create a seamless line of gorgeous inground illumination.

.png)

Protection against dust and water

Our reputation as the industry leader of industrial luminaires means we’re no stranger to tough environments. We apply this philosophy and commitment to durability just as stringently to our architectural products. Encapsulation technology allows our luminaires to be protected to IP66 - completed protected against dust and grime and highly protected against water ingress - including torrential rain and storms, ocean spray and high-pressure washing jets.

What’s an IP Rating?

The IP rating of each product defines the level of protection of an enclosure against intrusion from foreign bodies and moisture. IP ratings are an important indicator of how protected the electrical enclosures will be in a particular operating environment.

What do the IP rating numbers mean?

The digits that follow IP each have a specific meaning: The first digit (1 – 6) indicates the level of protection from foreign bodies, such as tools, dirt and dust. The second digit (1–8) defines the protection level from various forms of moisture, all the way from condensation to full immersion.

In-house IP testing

We test each product in-house to establish an IP rating for our luminaires. All encapsulated luminaires perform to IP66, both fully protected from dust and wave like water jets in all directions. As well as protection from ingress, the surface of the luminaire remains undamaged with no pitting or frosting when subjected to these conditions.

Ingress Protection Test

20 cycles of water jet test performed for 3 minutes, in multiple directions, multiple times, according to AS 60529-2004. The result: Luminaires in perfect working order with no visible damage to the surface.

High-Pressure Washing

Test This test checks the resistance of the material to power washing and demonstrates its strong resistance to pressure impact. Tested with 50 °C at 45cm and with a nozzle tip water pressure of 7 MPa. The result: No visible damage, free from deformation, lifting, peeling, wrinkling and cracking.

Need full luminaire immersion?

We go to painstaking lengths to ensure our luminaires perform - we don’t take any chances. If water immersion is required - connections are critical. For this application we offer gel-filled polycarbonate profile LED strip up to 2.5 metres in length. When equipped with two-metre Teflon cables and terminated in a dry location, the strip is suitable for constant water immersion (IP68).

Stability under harsh environmental conditions

Ingress protection is not the only benefit of our encapsulation – the process protects luminaires in severe weather conditions over long periods of time, and the material remains stable. When subjected to these real and simulated environmental conditions, no yellowing occurs, and the material remains optically clear with no changes in hardness or loss of gloss from the surface.

Heat Resistance & Thermal Shock Test

Cycled from -20°C to 60°C for 1,000 cycles over 30 days. Cycled 40 hours at 80°C (maximum operating temperature

Long Term Weathering Resistance Test

Cairns climate: High humidity with high temperature. Coober Pedy climate: Very dry & very high temperature. Real-world test conditions over two years exposure.

UV & Salt Spray Resistance Test

Xenotest simulates sun and rain exposure with an accelerated 10-year exposure period. Tested for 2000 hours at 65°C with a cycle of 102 minutes of UV, followed by 18 minutes of water spray.

UV & Condensation Resistance Test

QUV-A test simulates the action of sun and condensation on the material with an accelerated 10-year exposure period. Tested for 2,000 hours with a cycle of 8 hours at 70°C with a 340nm UV Lamp, and 4 hours at 50°C with condensation.

Acid Rain Resistance Test

Acid rain is simulated in a chamber with an atomised sulphur dioxide solution in distilled water. Tested for 8 hours at 2°C with a 600ppm SO2 solution.

Resistance to mechanical stresses

Our encapsulation technology creates a durable product, filling cavities, reinforcing the overall structure and enhancing the mechanical properties of our products. Luminaires are protected from bumps, knocks, drive over forces and other forms of mechanical impact.

Stone Chip Resistance Test

This test checks the resistance of the encapsulated product to impacts from gravel. 500g of chilled iron grit applied at an angle of 90° and a pressure of 2 bar, according to ISO 20567-1.

The results: No visible damage.

Impact Resistance Test

IK08 test: luminaire placed of a flat surface subjected to an impact equivalent to 5 Joules (1.7kg at 300mm), according to AS/NZS 1158.6:2010. Luminaire retested for IP rating after IK test. The results: Luminaire remains operable with superficial marks and no damage to the polyurethane surface.

Self-healing properties

The advanced resins used for encapsulation safeguard and protect components from external threats in multiple ways. The surface of the protected luminaire has a remarkable ability to resist wear and self-heal from surface marks caused by normal use.

Wear Resistance Test

The Crockmeter test ASTM D6279 checks the resistance to continuous cleaning with cloths, mops and sponges. Tested for 200 cycles with white crock cloth and green felt (M238C4). The results: No abrasion marks and no colour changes.

Abrasion Resistance Test

The Taber Test ASTM D1044 checks the resistance to drive over and walk over, performed by an abrasive wheel. Tested for 1000 cycles with a 500g wheel of medium abrasion (Taber CS-10). The results: Minimal abrasion marks.

Unaffected by cleaning agents

Our encapsulated products are resistant to many harsh chemicals, such as those found in common cleaning products and disinfectants that are likely to be used in a commercial, healthcare or residential setting.

Detergent & Disinfectant Resistance Test

These tests check the effects of prolonged, regular contact with common cleaning products:

- Household bleach

- Hydrogen Peroxide

- Common detergents (like Spray n wipe)

- Common disinfectants (like Pine O Cleen, Dettol)

Tested for 2 hours of direct wet contact.

The results: No surface marks, no yellowing and no loss of gloss.

Reliability. Always.

Coolon’s dedicated team of electronic engineers, mechanical designers and software developers continually aim to push the boundaries of technology. Clever design and innovative thinking are central to our drive for premium lighting products. Each product designed at Coolon is subject to hours of scrutiny, rigorous testing and evaluation, ensuring adherence to standards and regulatory requirements, both locally and internationally. Manufactured entirely within Australia, our products are created to deliver the ultimate quality and years of reliable performance.

Coolon Is Your Project Partner!

We’re not just another luminaire manufacturer. In addition to tailoring site-specific product solutions, Coolon and our partners supply lighting calculations, wiring schematics, maintenance manuals and training and provide in-house show and content creation, support and commissioning. We aim to understand the objectives of our clients and provide world-class solutions with our consultative approach. Every step of the way, we are determined to deliver an exceptional product and unparalleled service – we don’t compromise on the details.

Please feel free to reach out. We look forward to working with you!

Let’s Talk Shop with Nate: Episode 1 - Coolon

Let’s Talk Shop with Nate: Episode 1 - Coolon

20 • 01 • 2025

Join us as we kick off this exciting journey with Andrew Orkin, Product Development Manager at Coolon.

Coolon original podcast coming soon

Coolon original podcast coming soon

10 • 01 • 2025

We are excited to introduce "Let's Talk Shop with Nate", Coolon’s first-ever podcast dedicated to exploring the world of IoT products and services. The podcast will officially premiere on January 20, 2025, on YouTube.

Digitalization in Mining Australia 2024: Coolon is a speaker

Digitalization in Mining Australia 2024: Coolon is a speaker

24 • 10 • 2024

We’re excited to announce that Coolon will be both a speaker and an exhibitor at the Digitalization in Mining Australia 2024.